QUESTIONS? WE HAVE ANSWERS!

Online Application FAQs

To be considered for our Program, applicants MUST complete an application online.

For complete details on our application process, please CLICK HERE to visit our Applicants page.

Yes! Please watch our detailed, instructional video:

- Birth Certificate

- High School Diploma/GED/Equivalency Certificate

- If applicable:

- Certified Welding Tests

- Welding Class Certificate from Vocational/Technical Schools

- For Military Veterans ONLY: DD214 Report

Doing so simplifies the process by allowing applicants to upload the required documents using a smartphone (or tablet’s) camera.

- Be sure to take photos of your documents BEFORE starting the application

- When you select the ‘Choose Files’ button select the ‘Photo Library’ or ‘Choose Files’ options.

- Select all items to be uploaded.

- Once multiple images/files are selected, hit the add button

Typically, information is missing or incorrect. Be sure that:

- ALL required fields are completed

- ALL check boxes have been checked

- ALL required documents have been uploaded

- ALL required documents are in the correct file format. Only PDF, JPG, JPEG, PNG files are acceptable

- Make sure file sizes are under 3MB each

Depending upon your device, there are several methods for reducing file size.

One of the easiest methods for iPhones/iPads is to email the photo to yourself and during the process scale the file size through the dialogue box (as seen in the image below):

For android devices, click here for some suggestions.

You may use any electronic device (laptop, desktop, Chromebook, etc) to apply.

Regardless of device, just be aware applicants will need to upload documents as part of the process – so be sure you have electronic versions of the required documentation.

First, after successfully submitting your application the following message that will appear under the SUBMIT button: Your submission was successful. You will receive an email confirmation shortly. If you do not receive our email, be sure to check your spam folder.

Second, as indicated above, you will receive a confirmation email to the email address you entered when applying. If you do not receive the email, please check your spam folder.

General FAQs

The Union Boilermaker craft is comprised of a multifaceted, highly skilled workforce that helps to sustain every form of American industry.

At one time, anything that operated by steam fell under the Boilermaker work jurisdiction. Nowadays, the power generation industry is vastly dependent on the skills that Boilermakers provide.

Since we organized in 1881 – through the present time – the scope of work has grown to be one of the premier trades which service the following industries: Nuclear, Fossil, Hydro-electric, Waste to Energy, Tidal & Geo-Thermal, Steel, Petroleum, Chemical, Paper Mills, Breweries, Wineries, Mines, Recycling Plants, Sewage Treatment Plants, Bio-Diesel, Flex-Fuels, Ethanol Plants, Canneries, Schools – plus numerous other facilities.

Boilermakers fabricate, install, erect, dismantle and maintain the components and structures from the Light Commercial through the Heavy Industrial sector (tanks, process towers, smokestacks, etc.).

Boilermakers make, install, and repair boilers, vats, and other large vessels that hold liquids and gases. Boilers supply steam to drive huge turbines in electric power plants and to provide heat and power in buildings, factories, and ships. Chemicals, oil, beer, and hundreds of other products are processed and stored in tanks and vats. Boilers and other high-pressure vessels are usually made in sections, by casting each piece out of molten iron or steel. Small boilers may be assembled in the manufacturing plant; larger boilers are usually assembled on site.

Following blueprints for installing boilers and other vessels, boilermakers locate and mark reference points on the boiler foundation, using straightedges, squares, transits, and tape measures.

Boilermakers attach rigging and signal crane operators to lift heavy frame and plate sections and other parts into place. They align sections, using plumb bobs, levels, wedges, and turnbuckles. Boilermakers use hammers, files, grinders, and cutting torches to remove irregular edges so edges fit properly. Then they bolt or weld edges together.

Boilermakers align and attach water tubes, stacks, valves, gauges, and other parts and test complete vessels for leaks or other defects. Usually they assemble large vessels temporarily in a fabrication shop to insure a proper fit before final assembly on the permanent site.

Please CLICK HERE to visit our Video page to learn more about the Boilermakers trade.

Boilermakers perform the following skills:

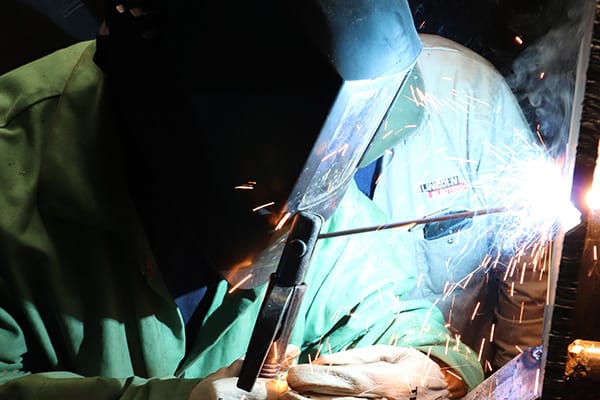

- Major concentration on High Pressure and Structural Welding, along with various cutting procedures is used. Our welders must qualify with many processes, procedures and metallurgy. We employ the latest technologies to meet the ever changing worksites.

- Rigging, signaling, and hoisting materials and equipment from small winches through the largest cranes in the world

- Steel fabrication, erection and dismantling

- Inspection and testing

- Scaffold erection and dismantling

- Blueprint interpretation

- Bolting and torquing of pressure vessels and structural components

One of four individual areas, we are the Boilermakers Northeast Area Apprenticeship Program. Geographically, we represent apprentices from nine individual Field Construction Local Lodges and Zones located solely in the Northeast region of the United States.

One of four individual areas, we are the Boilermakers Northeast Area Apprenticeship Program. Geographically, we represent apprentices from nine individual Field Construction Local Lodges and Zones located solely in the Northeast region of the United States.

Specifically, our apprentices work in the jurisdictional areas of:

- Local Lodge No. 5, Zone 5 – Floral Park, Long Island, NY

- Local Lodge No. 5, Zone 7 – Orchard Park, NY

- Local Lodge No. 5, Zone 175 – Oswego, NY

- Local Lodge No. 5, Zone 197 – Albany, NY

- Local Lodge No. 13 – Newportville, PA

- Local Lodge No. 28 – Eastampton, NJ

- Local Lodge No. 29 – Avon, MA

- Local Lodge No. 154 – Pittsburgh, PA

- Local Lodge No. 237 – East Hartford, CT

*Individuals interested in a Boilermakers Apprenticeship outside of the Northeast Area are encouraged to visit the International Brotherhood of Boilermakers National Apprenticeship Program’s website for more information.

Important items to consider:

- Work performed by boilermakers requires high technical skill and dedication to top performance.

- Field construction work is by nature an outside job which means exposure to all types of weather conditions, including extreme heat and cold.

- Boilers, dams, power generation plants, storage tanks, and pressure vessels are usually of mammoth size; therefore, a major portion of boilermaker work is performed at great heights, often from 200 to 1000 feet above the ground.

- Field construction and repair work is contract work; so, when the contract is completed, the job is ended. You may have to travel the territory of the local lodge and live away from home for long periods of time.

- The size of the materials, tools, and equipment handled by boilermakers requires excellent physical strength and stamina.

- To become a journeyman Boilermaker you must complete a minimum 6,000 working hours, forty-eight (48) online self-study lessons, on-the-job training booklets and classroom instruction (minimum of 144 hours a year). The average Boilermaker Apprenticeship typically takes four years to complete.

To be considered for our Program, applicants MUST complete an application online.

For complete details on our application process, please CLICK HERE to visit our Applicants page.

Applicants must meet the following requirements:

- Be 18 years of age

- Must have graduated from high school, or be able to provide an equivalency certificate

- Be willing to participate in alcohol and drug testing within 48 hours after signing the apprenticeship agreements

- Have reliable transportation to the related instructions and to travel long distances to job sites

- Be physically able to perform the usual tasks required in the Boilermaker Trade as determined by a verbal declaration

Applicants are divided into four Pools of Eligible Applicants:

- Pool I Applicants posses Certified Tube (Pipe/TIG/SMAW 1G-6G) Welding Certificates

- Pool II Applicants posses Certified Plate (MIG Plate/SMAW Plate) Welding Certificates

- Pool III Applicants posses Vo-Tech or Welding School Certificates (regardless of welding process studied)

- Pool IV Applicants posses no certifiable welding skills

The Boilermakers Northeast Area Apprenticeship Program will not discriminate against apprenticeship applicants or apprentices based on race, color, religion, national origin, sex (including pregnancy and gender identity), sexual orientation, genetic information, or because they are an individual with a disability or a person 40 years old or older.

The Boilermakers Northeast Area Apprenticeship Program will take affirmative action to provide equal opportunity in apprenticeship and will operate the apprenticeship program as required under Title 29 of the Code of Federal Regulations, part 30.